RIPRIL Process Technology Pty Ltd (Mineral recovery)

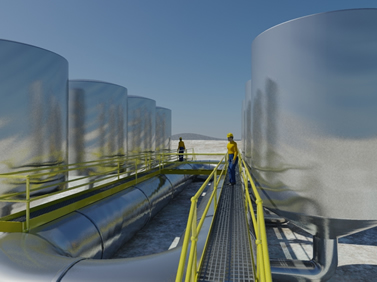

Mineral Contactor and Elution Circuit

Resin in Pulp (RIP) processes can provide specific challenges to mining companies developing rare earth mineral IX recovery circuits.

Resin in Pulp (RIP) processes can provide specific challenges to mining companies developing rare earth mineral IX recovery circuits.

The Australian mining industry is beginning to move towards RIP and there are pilot studies underway and planned demonstration plants.

IX Resin loading, resin attrition (wear, breakage, process loss) and scale up from pilot - demonstration - full scale Mega Flow production equipment are seen as major challenges.

Traditional process methods of RIP are known to have high resin wear and attrition resulting in reduced resin life and higher operating costs. The resin bead degradation is generally caused by the action of agitation blades and fine pulp particle contact during the contactor stage and pumping of the resin during transfer to elution circuits etc, loss of resin due to process inefficiencies have raised significant concerns that resins may not be an economical approach if high replacement is necessary.

We have designed a new innovative process concept for mineral recovery for Resin in Pulp (RIP) and Resin in Leach (RIL) which addresses all current industry concerns and we believe could provide clients with high flow and loading capacities for large scale projects.

The RIPRIL process could be used to recovery base metals and rare earth minerals such as Nickel, Uranium, Gold, and Copper, minerals which are present in pulp or leach liquors using Ion Exchange Resin in the recovery kinetics.

This process involves:

Benefits

- Resin degradation is minimised

- Minimal resin attrition due to system design

- Eliminates agitator circuit (no mixer blades)

- No resin - pump contact

- Provides efficient resin / pulp surface contact (good kinetics)

- Minimises ionic leakage by recycling of tailings

- More efficient loading cycle

- Variable process control of all flow cycles, contactor, transfer, elution, precipitation etc

- Provides for both small pulp / leach flows to Mega Flow

- Provides a continuous batch contactor and elution circuit

- Allows for transfer from laboratory analytical apparatus to pilot plant and mass production plant scale with design accuracy.

- Both Cationic and Anionic resins, Gel and Macroporous can be used (Strong and Weak Acid and Strong and Weak Base)

- Simultaneous dual mineral recovery

- Designed for computer control and monitoring

Eliminates

- Resin to pump contact and resin deterioration

- Agitator abrasive resin wear in contactor cycle

- Abrasion of resin when contacted by suspended pulp particles

- Resin losses in process system

- Scale up problems (pilot to production design)

For process details refer to Australian Patent No. PCT/AU2009/001489

Contact

Noel Priestley,

Director

RIPRIL Process Holdings Pty Ltd

ABN 851 33922291

Phone : (+61 8) 8270 6878

Fax : (+61 8) 8270 2421

Mobile : (+61 0) 408 496 441

Email: Noel.Priestley@permusoft.com.au